New Doming System with UR Robot

See YouTube video

Doming Technology for the Processing of Silikon, Polyurethane and UV Doming

WELCOME TO DOMING MACHINE!

Our approach to doming is always a comprehensive and personalized process for each customer. From installation to launch, we follow an accurate and reliable plan to accompany you through the entire project.

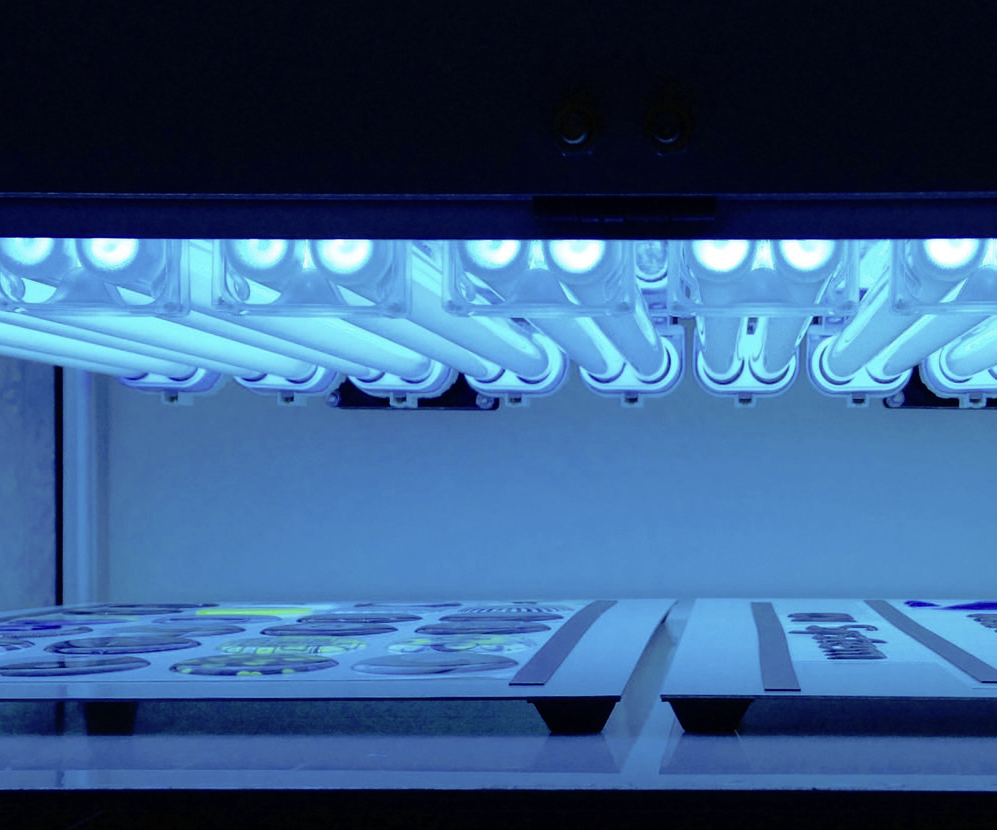

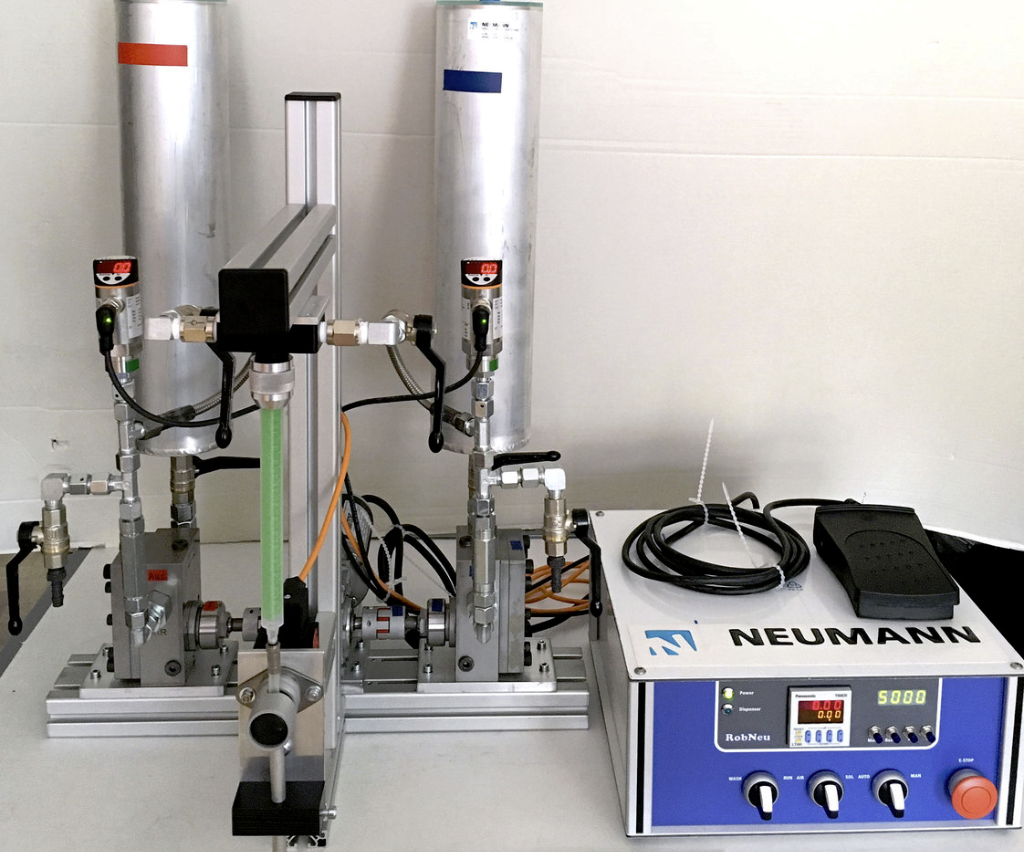

We build doming machines and develop doming technology for the production of 3D stickers, including LED and electronic potting.

For further information about our polyurethane and UV resin products, including material prices, please click on the pdf files below.

We also deliver high quality doming material. MADE IN

GERMANY

Doming technology requires high-quality materials, such as polyurethanes and UV doming material, which are available to you. We have over 20 years experience in doming technology (polyurethane and UV doming) and can advise you on all your doming requirements. We build the doming machines for you and provide you with all your doming material needs.

Good to know: 2K polyurethane consists of isocyanate + polyol

When mixing isocyanate and polyol with each other, a chemical reaction occurs resulting in a new substance. The new substance is a clear polyurethane glass (disposed of isocyanate) and is non-hazardous.

Our Resin is developed and produced in Germany according to the current, and prepared for future EU standards.

From 2020, EU manufacturers will have special requirements for doming material with dead heads (isocyanates). This is not necessary for our doming material.

No danger good = cheaper in transport.

no danger good = suitable for furniture industry.

2K Polyurethane Features:

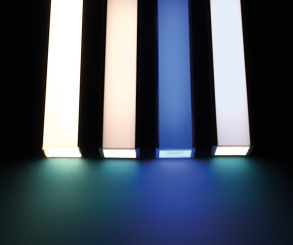

- Highly transparent

- Very strong adhesion

- RoHS Compliant

- Mercury free

- Non-hazardous/dangerous goods

Our container sizes:

- 2K PU doming resin availabe in 1, 5, 10, 25,200 and 1000 Litres IBC (Doming PU 2016 / Doming IC 300).

- UV doming resin available in 1, 5 and 10 Litres.

Impressions from our booth at FESPA 2019 München

Impressions from our booth at FESPA 2018 Berlin

Impressions from our booth at FESPA 2017 Hamburg

FURTHER TECHNICAL INFORMATION

Doming material description and price - [...]

PDF-Dokument [109.7 KB]

Technical Datasheet Doming PU 2016 M12 -[...]

PDF-Dokument [336.6 KB]